- Timber Cladding

- Hardwood Decking

- Landscaping & Infrastructure

- Interior Timbers

- Exterior Timbers

- Timber Flooring & Panelling

- Crossarms, Poles & Piles

- Gallery

- Market News

- Information Resources

- Our Sourcing Policy

- Contact

- About Us

Market News

Recessed windows: combining high performance with Northern European aesthetics

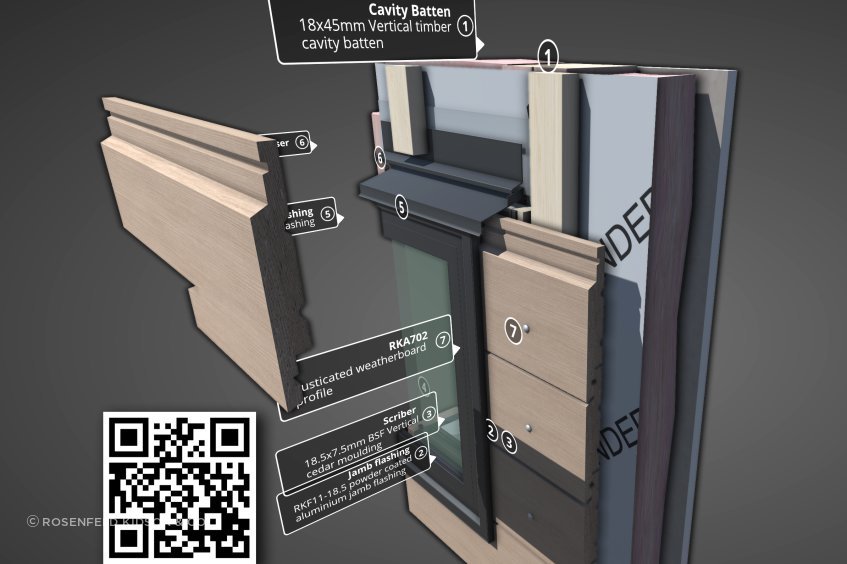

Rosenfeld Kidson's recessed window flashing system simultaneously looks striking, performs well in terms of weathertightness and thermal efficiency, and is easily installed.

Words by ArchiPro Editorial Team - 13 December 2022 - 3 min read

In the current era of the construction industry in New Zealand, thermal efficiency and weathertightness are one of the most significant and often discussed issues. With some of the H1 changes to the Building Code coming into effect this year, and more to come throughout 2023, it’s imperative that the industry gets on board with solutions that prioritise these two crucial elements.

Windows are one of the most significant vectors through which heat can escape a home, so naturally they are one of the primary considerations when insulating. And when it comes to windows, New Zealanders have a love affair with aluminium joinery: it is, by far, the most common joinery material for windows. But in the wake of the Building Code changes, aluminium joinery will need to up its thermal efficiency game in order to comply.

There are several ways to do this. To improve thermal efficiency, aluminium can be thermally broken – but this doesn’t address the issue of weathertightness. Recessed window flashing systems, on the other hand, can improve both insulation and weathertightness performance simultaneously.

Rosenfeld Kidson, a New Zealand owned and operated company that stocks a huge range of over 50 species of specialist timbers, has an especially dominant expertise in this field: its INTERSET recessed window flashing system for both vertical and horizontal shiplap has stood out in the industry for many years.

A host of benefits

Ray Hutton, the company’s National Marketing and Specification Manager, says the act of setting the joinery back to the frameline – or ‘recessing’ the joinery – creates several benefits for the performance and aesthetics of windows.

“The INTERSET creates a 65mm deep recess to the head, sill and jamb line,” says Ray. “The system consists of a set of aluminium flashings and thermoplastic stop-ends that interlink to form a ‘picture-framed’ window recess – both of which work to improve the weathertightness and thermal performance of the window itself.”

The INTERSET system sets itself apart by virtue of its ability to be installed on not just vertical but modern horizontal rusticated boards. In fact, it was developed eight years ago with vertical weatherboards in mind – used especially in conjunction with western red cedar, truwood and larch timbers.

“As far as I know, there is no other timber recessed window on the market in New Zealand that is designed specifically for vertical weatherboards – so it is quite unique,” says Ray. “I think it’s this uniqueness that has played a big part in INTERSET becoming so well-established in the marketplace.”

An eye-catching, easily installed system

But, Ray goes on to say, the performance and unique installation potential aren’t the only benefits of the system. In addition to its ability to be installed on a wider variety of weatherboards, the installation of the system itself is also very straightforward.

“We have a really clever 3D modelling system called WorkingSpec, which builders can use in conjunction with INTERSET,” says Ray. “The builder just needs to download the app, and simply tag the QR codes – which brings up an extremely targeted 3D imaging interface which is highly interactable. It can be rotated and expanded, and you can track back and break down the build process to the key phases of installation.”

But even with the myriad of physical benefits, Ray says the system has endured throughout the years primarily because of its aesthetic appeal. Not just because it’s well-suited to vertical shiplap – a trendy weatherboard format that continues to rise in popularity around Aotearoa – but also on its own visual merits.

“Its main aesthetic benefit is that it adds relief to the façade,” says Ray. “Often, face-mounted joinery can look quite boxy – it can look like it’s ‘pushing out’ the cladding. Having a recessed option creates shadow lines, adds depth – both literally and figuratively – and it lends the façade a higher-end Northern European design aesthetic.

“Clients want to have all of these elements in their windows – weathertightness, thermal efficiency, ease of installation and aesthetic appeal,” says Ray. “And with INTERSET, I think we deliver this really well.”

Learn more about Rosenfeld Kidson and its recessed window flashing system.

A timber company’s bold move to a sprawling two hectare site

Last year, Rosenfeld Kidson made a big move: it commissioned a brand new manufacturing site in Papakura, where it imports timber, houses its state-of-the-art processing equipment, and hosts its dispatch operation — shifting most of these operations from Mt Wellington to Papakura.

Words by ArchiPro Editorial Team29 June 20224 min read

For companies that have been around for a long time, moving around is a common occurrence.

Celebrating the 90th anniversary of its incorporation three years ago, specialist timber company Rosenfeld Kidson is no exception: it’s continually evolved throughout the decades as the industry and country around it changed — including a general expansion of its business, and the opening of multiple new locations and warehouses.

From the 1930s until the mid 1990s, the company operated from the Strand in Parnell. Then, in 1996, it moved to a purpose-built premises in Mt Wellington, complete with a drive-through warehouse and 3000sqm of covered storage.

Last year, the company made its second big move: it commissioned a brand new manufacturing site in Papakura, where it imports timber, houses its state-of-the-art processing equipment, and hosts its dispatch operation — shifting most of these operations from Mt Wellington to Papakura.

The sprawling 2.2 hectare site also includes a small office, which doubles as a showroom to feature Rosenfeld Kidson’s products in a variety of end uses.

Mark Liggins, the managing director of Rosenfeld Kidson, says the move is symptomatic of the company’s trajectory in the last few years, and resulted from it outgrowing the Mt Wellington facility.

“It’s allowed us to have a lot more space,” says Mark. “We now have an additional 4000sqm shed and 7000sqm of concrete. What this means is that we can have all our operations on a single site.”

The sprawling 2.2 hectare site also includes a small office, which doubles as a showroom to feature Rosenfeld Kidson’s products in a variety of end uses.

An opportunity for growth and elevated productivity

A significant factor in the decision to move to a larger space was the unpredictability and volatility of the global supply chain. Recently, Mark says, there has been reduced availability of timber and fewer ships coming here than usual — and when they do come, a lot of containers arrive simultaneously. This meant the company had to re-visit its logistical operations, procurement strategy and exposure to global supply chains.

“In Mt Wellington this presented a challenge — but on our new site, logistics are easier, and we can efficiently handle multiple containers at once,” he says. “An excess of space also means that we can have more stock and don’t have any problems accessing dry timber now, enabling the company to be more agile, supporting our innovative and creative business model.”

In addition to receipt of containers for de-vanning and inspection, it’s also enabled the company to enhance the efficiency of other integral processes – like timber grading and drying, order selection, timber profiling, coating and dispatch.

The entire timber operations and then production process can be done quickly and efficiently in the ‘machine shop’, which takes up half of the entire warehouse. This is where, once the orders have been selected, the timber is recut through a bandsaw, after which it goes through a planer to profile it. Following that, it gets pre-coated — after which it will be packaged and dispatched.

The premium timbers are then utilised in a variety of finishing timber applications — including exterior cladding, solid timber flooring, wall and ceiling panelling, exterior decking and joinery.

Rosenfeld Kidson enlisted the expertise of SGA Architects and Steve Joynes — a top residential architectural builder — for the project.

Showcasing the best in timber products

Part of this can be seen at the new showroom on the Papakura site. “The aim of this showroom is to give an impression of the essence of what we do,” says Mark. “We display our cedar cladding, in this case, as a 28mm thick weatherboard; there’s our recessed window flashing system, which allows traditional aluminium joinery to be set back from the façade; as well as custom fascia and panelling.

Rosenfeld Kidson enlisted the expertise of SGA Architects and Steve Joynes — a top residential architectural builder to create and execute some impressive junction details, again showcasing what the use of these timbers can achieve.

“For the interior, there’s multiple timber uses for interior joinery, solid timber flooring, wall panelling and furniture — all in American white oak, which is a very beautiful and great performing timber in these areas.”

There is also a ‘courtyard area’ connected to the showroom, which features some of Rosenfeld Kidson’s exterior hardwoods used for exterior furniture and decking.

And in addition to all the extra space and added efficiency the site offers, Mark says it also presents a great opportunity for specifiers, architects, builders and other professionals to visit and understand the entire process of imported timber handling, manufacturing and installation.

“It finished construction at the end of last year, and already it’s been a huge success,” says Mark.

Learn more about Rosenfeld Kidson, its new site and its products and offerings.Thoroughly modern cladding

Rosenfeld Kidson’s classic bevel back cedar weatherboards are increasingly being used in alternative ways to produce a bold architectural statement.

Words by Justin Foote - 17 March 2020 - 2 min read

When the early sealing gangs set up home in New Zealand in the late 1700s, they brought with them building techniques best suited to their profession—that being ship building. Those skills coupled with the abundance of timber also meant that building with wood rather than stone was an obvious and expeditious choice and so began the Kiwi love affair with weatherboards.

The term ‘weatherboard’ has been associated with cladding since the mid-1500s and while the name may change from region to region around the world, it remains a popular style of cladding. In suburban Auckland in the 1940s and 50s, weatherboards reached a new prominence in the architecturally designed homes of Vernon Brown, whose white trim, black-stained weatherboard houses became—and remain—highly sought after.

Today, our weatherboards tend to be predominantly made from western red cedar, are available in a range of widths and can be oiled, stained or painted depending upon the look you wish to achieve.

Rosenfeld Kidson’s Bevel Back Cedar weatherboards provide a classic design element to any external cladding system.

Weatherboards as an architectural statement

For its Wanaka Crib project, PAC Studio used a variety of bevel back cedar weatherboard widths—arranged from narrower at the base to wider at the apex, says Ray Hutton, Rosenfeld Kidson’s national specification manager.

“The versatility of our bevel back cedar weatherboards gave the architects creative licence to achieve an extraordinary level of detail and finishing. The weatherboards used in this instance exemplify the very best of how traditional materials can fit into a modern yet simple brief.”

According to architect Aaron Paterson: “The choice to use differently sized boards was to create the sense that the base of the house has, over time, been compressed by the weight of gravity, much like the surrounding mountains, embedding the structure in the very bedrock on which it sits. Additionally, the graduated weatherboards, being teamed with the razor-thin roof edge, are part of a design strategy to exaggerate and abstract the southern-gable-shed form synonymous with the region.”

Cedar provides stunning design flexibility that will deliver longevity, performance and style.

Working together to create a lasting finish

Rosenfeld Kidson is proud to have played a role in realising the homeowners’ dream for their home, says Ray.

“Our dedicated team worked with PAC Studio during the design stage, helping to bring to life their brief for a unique board layout, complex detailing and colour consultancy for the Wanaka Crib project.

“We believe it is this collaborative approach that we take with architects and designers—as well as the end user—coupled with their vision to push design boundaries that continues to result in these exceptional outcomes and why weatherboards continue to resonate with homeowners.”

The colour and finish of weatherboards can be manipulated to suit most tastes and to respond to whatever environment the building may be found.

Behind the scenes of your weatherboard system

The Rosenfeld Kidson Cedarscreen weatherboard system comprised a 20mm cavity, 28mm thick band sawn weatherboards and extruded, powder-coated flashings that added stability to the varied width Bevel Back boards and supported the uniquely lapped and mitred corners. As always, the weatherboards were factory oiled prior to delivery and were finished with silicon bronze, face-fixed nails.

Find out more about bevel back cedar weatherboards.

The thermally modified wood revolutionising timber cladding

A chemical-free heat-treated timber combined with innovative new detailing is opening up a world of possibilities for residential cladding...

Words by ArchiPro Editorial Team - 16 October 2019 - 3 min read

A chemical-free heat-treated timber combined with innovative new detailing is opening up a world of possibilities for residential cladding design in New Zealand. We spoke to Rosenfeld Kidson & Co about the Truwood® difference.

Manufactured in northern Europe, Truwood is made using the world’s best thermal modification technology. The result is a unique and beautiful appearance; a rich, caramelised colour similar to Teak - a colouring that’s achieved not with treatment or stain, but with heat.

“The beauty of Truwood is that it’s chemical free,” Rosenfeld Kidson’s Ray Hutton says. “It is created using state-of-the-art thermal modification technology. The process sees the timber heated to between 160 and 230 degrees Celsius and exposed to water vapour and pressure. The modification changes the appearance of the wood and creates the beautifully rich colouring.”

Thermal modification changes the cell structure of the timber, turning it into a much more stable and durable material that has less expansion and contraction in changing climatic conditions.

The increased stability achieved with thermal modification also allows for new levels of detailing and design. As such, Rosenfeld Kidson has redesigned their systems to expand on the creative licence thermally modified timber allows.

“The improved stability of thermally treated wood means detailing can be achieved in new and innovative ways we haven’t been able to create until now,” Ray says. “With a new range of extruded aluminium flashings whose origins are in the very best of European architecture , we’re able to offer new joinery details including a range of sleek internal and external corners.

“Truwood and the revamped detailing options give architects and designers much greater creative freedom and present a new level of opportunity for residential design in New Zealand.“These latest developments are part of our aim to push the boundaries and redefine how timber is used as a cladding material.”In comparison to other timbers, Truwood has an attractive price point, making it more accessible to a wider range of consumers.

A clear grade, low density hardwood, Truwood is sourced from FSC-certified forests. It is not laminated and is supplied in solid sections with an even colour and attractive grain pattern.

“Globally, modified timbers are making an increasing inroad into the construction industry as availability increases and its benefits are realised. Ultimately, Truwood offers increased durability, stability and aesthetic value and is a renewable timber that is now readily available in New Zealand in clear, long lengths,” Ray says.

“Truwood has a Durability Class 2 rating and is considered more durable than other naturally durable cladding types available. Truwood is also very stable, due to the modification process. Since the cell structure of modified wood absorbs less water, the equilibrium moisture content of the timber is also reduced. Improved dimensional stability reduces movement in service such as cupping and warping.”Truwood is profiled in accordance with NZS3617 and Branz Bulletin 411, with both vertical and horizontal profiles compatible with all standard Rosenfeld Kidson system details. “An additional benefit of the reduced movement in service is the increased performance of coatings.

Rosenfeld Kidson factory coat Truwood in a specifically formulated modern wood stain Natuetone®. This water-based stain has excellent water repellency and further improves the performance of the timber, while providing a range of natural colour options from grey to mid-brown, to walnut and black.”

Truwood is also well suited to many other applications. Its relative low density makes it great for fascia, window frames, door, sliders, garage doors, louvres and gates, as well as other internal joinery applications.

Find out more about Truwood and thermally modified timber.

From the beaches of Oahu to Aotearoa: the rise of oiled cedar

Vertical cedar cladding has quickly become a coveted choice for homes around the country. We had a chat to three men who are behind its swift integration...

Words by ArchiPro Editorial Team - 16 August 2019 - 4 min read

Vertical cedar cladding has quickly become a coveted choice for homes around the country. We had a chat to three men who are behind its swift integration into the Kiwi vernacular; architect Daniel Marshall, Ray Hutton of Rosenfeld Kidson and Jon Pearson of Dryden.

Omaha Beach House by Daniel Marshall

As a young architect, Daniel Marshall wandered along the beaches of Oahu’s north shore where his father lived and took in the local vernacular. Here, the extremes of salty air seemed to destroy almost all building materials, with Western Red Cedar the only cladding that survived. “Years later as a practicing architect, I had my first opportunity to design a beachfront home,” Daniel says.

That was some 16 years ago, and the house - on the banks of Omaha beach - still stands. “Cedar was an obvious choice for that project, given my Hawaiian observations, and conceptually we really wanted to push the idea of creating a house sculptured out of wood. To do this, we completely avoided using any steel structure or alternative cladding other than timber.”

The Omaha house was the beginning of a two-decade long collaboration between three key players in New Zealand; architect Daniel Marshall, Ray Hutton of Rosenfeld Kidson and Jon Pearson of Dryden. Together, the trio pushed the boundaries and forged the beginning of what is now a coveted cladding option for our coastal environment: Western Red Cedar.

For Ray, cedar cladding has been a lifelong passion, and it’s Ray who has worked tirelessly over the years developing acceptable alternative solutions for vertical shiplap cedar cladding that are recognised as a compliant alternative to Building Code solutions. For Ray, like Daniel, the inspiration came from overseas, but in this case Europe rather than the Hawaiian islands.

Prior to the late 1990s, Western Red Cedar had not featured widely in New Zealand architectural houses, but thanks to the development of a range of innovative solutions for cedar cladding, its use has increased quickly and significantly, with it now being the cladding of choice for many architecturally designed homes.

However, the technical elements of the Western Red Cedar cladding systems are one part of a combined effort. In order to ensure their durability and a coveted range of ever-developing hues, the partnership between Dryden, Rosenfeld Kidson and architect Daniel Marshall blossomed.

“Creating innovative technical solutions is one thing; ensuring the ultimate durability and aesthetic variations is another. That’s where Dryden and Jon Pearson come into the mix. What they have achieved has allowed for unparalleled stability and durability with our systems, creating a benchmark for the lifespan of cedar cladding in our harsh climatic conditions,” Ray says.

“What we’re always aiming to achieve is an improved aesthetic in conjunction with a technically excellent solution. What we needed was a timber that could outperform as a cladding solution and retain its aesthetic qualities for longer than its counterparts.”

Omaha Beach House by Daniel Marshall Architects

The use of Dryden WoodOil meant projects such as the Omaha house designed by Daniel Marshall can stand the test of time, and there is a range of unique and customisable colours and finishes.

“The Omaha house was oiled with Dryden WoodOil in a colour known as slate, which created the look of pre-weathered cedar we were after. The oiled finish, with occasional reapplication has continued to patina beautifully and protect the cladding from the ravages of the ocean. The house looks better now than the day it was built,” Daniel says.

Dryden WoodOil is a non-filming oil that penetrates the wood rather than sitting on the surface as other oils or stains do, Ray says. “Because it’s a migrating oil, it is drawn into the timber protecting the timber from water, UV exposure and temperature extremes. This allows the cladding to remain durable and stable over time, and last for decades in our harsh climatic conditions. Together with the clever details of the cladding system, Dryden WoodOil offers an innovation solution that cannot be created with any other product currently available in New Zealand,” Ray says.

“Dryden WoodOils are playful products in terms of the creativity behind their extensive colour range, yet they are incredibly clever in make up, enhancing the look and feel of the wood. It’s imperative that the first coat of WoodOil is factory applied to ensure every part of the timber is penetrated. The second coat is then applied directly before practical completion of the house, and depending on the environmental context of the building, every few years after that.” Dryden has a national network of contractors who work with homeowners to ensure their homes are maintained over the years and extend the life of the product. “This is an essential offering that gives homeowners confidence that their investment will stand the test of time,” Ray says.

This year, Dryden WoodOil celebrates its 20th year in operation in New Zealand.

If you’re considering using Western Red Cedar cladding, make sure you visit Rosenfeld Kidson and Dryden on ArchiPro to find out more about the vast possibilities of this innovative combination of products, designed specifically for New Zealand conditions.

Omaha Beach House by Daniel Marshall Architects

Cedar cladding: It’s all in the detail

New Zealand’s climatic conditions can be extremely harsh on buildings so it is crucial that architects and designers get the creative details of a timber façade just right to ensure cladding will endure the ravages of time and also look amazing...

Words by ArchiPro Editorial Team - 07 March 2019 - 5 min read

New Zealand’s climatic conditions can be extremely harsh on buildings so it is crucial that architects and designers get the creative details of a timber façade just right to ensure cladding will endure the ravages of time and also look amazing.

Cedar has proven itself to be a reliable and popular choice as a building material for cladding in New Zealand. “Cedar is popular as you can do almost anything with it,” says Ray Hutton of Rosenfeld Kidson, suppliers of cedar, larch and other specialist timbers. “Its inherent stability gives architects and designers greater creative license to achieve the designs they’re after.”

“As a log, cedar is sustainably harvested, it dries quickly and machines profiles easily too,” explains Ray. “It’s the ultimate commercially-supplied softwood for exterior façades but the key benefit is that it gives us creative license to create many different profiles: to be able to add texture, depth and seamless transitions to the façade – to be very creative for the specifier, as it were.”

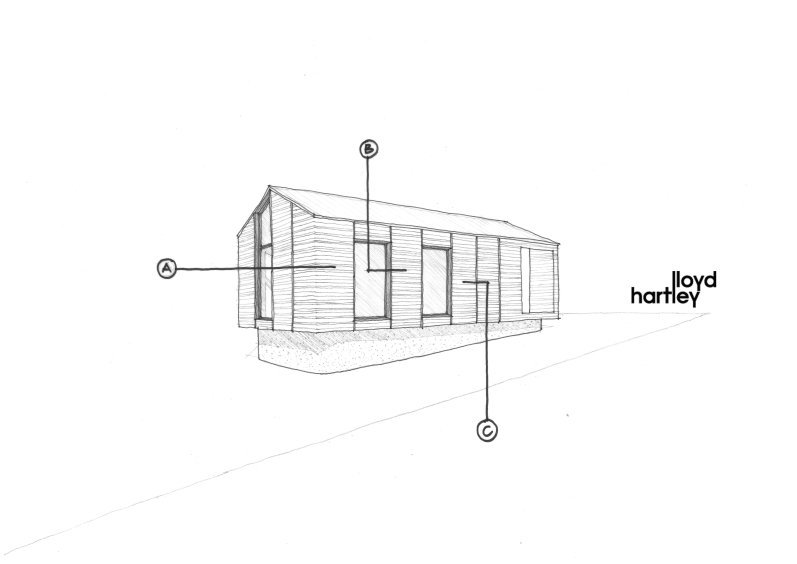

Lloyd Hartley's detail sketches of vertical shiplap cedar weatherboards shows the transition from weatherboard to weatherboard and relates to the sketch below.

In keeping with the current Kiwi design trend for ‘rustic modern’ or ‘contemporary rural’ style homes, popularity has grown for horizontal shiplap or ‘rusticated’ timber weatherboards as a cladding. But it is the junction details that are crucial to get right, suggests Ray.

“Recently, a client of ours designed a house that’s clad in modern rusticated weatherboard – running horizontal – and the detail they wanted was for the corners to be mitred and the horizontal line to be seamless from point to point. Linked to that, he also wanted to add relief to the façade by dragging the windows back to create recessed windows.”

Rosenfeld Kidson was able to provide a solution that achieved the desired look in a cost effective way, while also ensuring long-term, weathertight performance.

Ensuring these architectural details are perfect is something the team at Rosenfeld Kidson prides themselves on. “Linking into the ‘modern rusticated’ trend, one of the systems we designed many years ago was random-width cedar, where the boards are different widths, but people wanted to stagger that aesthetic in depth also and have the flexibility to make them thicker and thinner in either a horizontal or vertical line. So we created a vertical flashing detail that allows vertical boards to be run off horizontal weatherboards and vice versa.”

Ray explains: “Daniel Marshall Architects created some of the very first modernist Kiwi bachs and this was one of the first uses of vertical cedar where the façade was flush with the joinery, creating clean, crisp vertical and horizontal lines, which are now the quintessential Kiwi bach! This can be seen in the Lloyd Hartley sketches (above and below). The detail shows the transition from weatherboard to weatherboard in a vertical line.”

One of the main reasons that Rosenfeld Kidson has been able to work with specifiers on creating innovative solutions for architectural details is because it has invested heavily in modern machining methods.

“We have some of the best machinists and manufacturing capabilities in the country, which helps us to push creative boundaries,” explains Ray. “A key focus of our business is ‘design intent’ – to give the specifier what they want, hopefully before they even know they want it because we’re investing in research.”

The firm has been refreshing its company profile, including releasing a full set of new construction details. “We’ve just updated all of our Cedarscreen systems and these include new innovative details, such as the modern mitred-corner details for rusticated weatherboards, recessed windows and the interchangeable vertical junction,” Ray says. “We can also offer these in other timber cladding alternatives, such as Truwood® and European Larch.”

Lloyd Hartley's elevation sketch shows the transition from weatherboard to weatherboard. The A, B and C relate to the detail sketch above.

In recent years, Truwood has proven to be a very popular cladding material as it is a cost-effective alternative to cedar, with similar characteristics. “It’s a beautiful, homogenous, low-density hardwood that we have treated in Europe and manufactured in New Zealand to comply with our Building Code requirements,” explains Ray. “It’s available for use with all Cedarscreen systems and it has great dimensional stability, durability, colour and grain structure.”

Cedar is Rosenfeld Kidson’s core offering but it also imports many other speciality timbers. This range of sustainable hardwoods and softwoods offer many alternatives for different end uses.

Many of these timbers can be used in exterior as well as interior applications. Rosenfeld Kidson can match interior product profiles to the exterior weatherboards, creating seamless transitions for inside-out design schemes.

However, with a variety of timber species and tones now being used within one house design, homeowners and architects can be challenged to match the different timber tones.

In many instances different timbers are used and, according to Ray, “When choosing interiors, it’s about blending the timbers. Oils are drawn into the timber, rather than sitting on the surface, so you can rag on a dark colour and rag it off to make it more honey-like or add a white wash to make it pale, or a black tone to minimise redness and make it more of a neutralised brown. But, more often than not, the oils add an even lustre and depth to the timber to give you the right result.”

Ray suggests that homeowners link up with specialist people who can provide good advice. “I’m a big fan of the Dryden WoodOil products for exterior cladding because you can manipulate the colour on the timber to actually give you the tones you want and it is fantastic for the wood itself."

If you’re looking for advice about timber cladding, you can contact Rosenfeld Kidson on ArchiPro here.

How one New Zealand timber merchant is using technology to improve buildability

When New Zealand amended the Building Code to include cladding fixed on a cavity, the industry found itself with hundreds of projects that couldn’t get compliance...

Rosenfeld Kidson has always been on the cutting edge of innovation in the timber industry and they’re at it again with new 3D-animated installation instructions for their Cedar weatherboard systems. We spoke to Ray Hutton about the incredible tool that’s bridging understanding gaps for suppliers, builders, specifiers and architects alike...

Words by ArchiPro Editorial Team - 03 August 2018 - 5 min read

When New Zealand amended the Building Code to include cladding fixed on a cavity, the industry found itself with hundreds of projects that couldn’t get compliance. That’s because although the Building Code introduced the use of cavities, there was still no provision for cavities using horizontal battens, which are required for vertical shiplap weatherboard applications.

“This was when vertical shiplap was just becoming very popular. A simple solution was to turn the vertical boards horizontally, which was the birth of modern rusticated weatherboards.

“Rusticated weatherboards were traditionally manufactured with a 40 mm scalloped rebate, as seen on villas and rural buildings, which isn’t very architectural or creatively focused.

So we used our vertical boards and turned them horizontally. We took those same 9 mm deep, 6 mm wide negative rebated boards, put a slope on the top to form a drip edge and a slope on the bottom for drainage, and that was the advent of modern rusticated weatherboards.”

Since then, the Cedar industry has led the charge in terms of refining and modifying traditional timber profiles. Rosenfeld Kidson continues this innovation with all other aspects of their Cedar weatherboard systems. According to Ray, Rosenfeld Kidson’s commitment to quality and inventiveness is their key differentiator.

“With our Cedarscreen Rusticated weatherboards for example, we recognized that the window is by far the most critical element of a facade in relation to weather-tightness. We developed the system to achieve optimal weather-tightness with the use of our J mould and conceal- fixed scriber detail, which helps achieve a flush, yet weathertight solution. To further help with the buildability and visual aspect, we have created a new mitred external corner detail that not only simplifies the build, but also helps to seamlessly link the timber façade from face to face.

“We’ve consistently led the way with innovation and are very creative with detail. We’re all about simplifying the build and high-end architects love us because we give great advice on how to use the product.”

And they’re doing just that with an incredible new solution called Working Spec. The Working Spec app links animated 3D-models to QR codes on product details, brochures and architectural plans. Rather than interpreting confusing 2D drawings and brochures, a builder or specifier can scan the code to interact with a full 3D model of the product or solution on their tablet or mobile device.

Working Spec bridges the gap between manufacturer and end-user and overcomes the key issues with traditional instructions and even current 3D-modeling systems. While solutions do exist, they’re often software dependent, making 3D modeling out-of-reach for most builders and end-users.

Rosenfeld Kidson has been using the Working Spec app exclusively to showcase their systems for the last twelve months and, according to Ray, the difference has been monumental.

“Working Spec greatly increases the buildability of the detail. We have excellent literature, but this is the next level - a tool that shows exactly how certain details must be done. We’ve worked closely with our builders and taken on a lot of feedback to refine the experience and ensure they have the tools needed to achieve the right outcome.”

When you download the Working Spec app and scan one of Rosenfeld Kidson’s unique QR codes, you truly see the build come to life. Not only that, but you can hover over the animation, change your view, zoom in and read an exact description of certain components in the system.

“Working Spec breaks down barriers in understanding and simplifies the building process. Essentially, it’s a buildability tool that can be used to understand how products are designed and then executed on site.

In the past, we were working with 2D details and trying to explain technical details without enough context. To aid understanding, we’d usually send someone to the site and we found that this increased the time spent on each project significantly. Now, however, Working Spec does this for us and it does so in a way that’s consistent and can be shared easily.”

As Ray puts it, “This isn’t necessarily a new technology, but it’s being used differently. What’s great about the interactive instructions is that they’re dynamic. This isn’t a static 3D render; it’s an animated tool that allows you to understand the sequence of the build, as each element comes together.”

The most obvious advantage of Working Spec is that it increases the builder’s understanding and skill level, but Ray notes how the app has significantly improved Rosenfeld Kidson’s product reps’ knowledge as well.

“I work with some of the best technical sales reps out there, all of which are able to competently articulate information around the facade in an accurate manner.”

This, of course, stems from the fact that they just get it - as does anyone else with access to the 3D animations. Architects, specifiers and owners can all glean a full understanding of the build using the app. Plus, this information is all in one place, compared to the current system where product details are disjointed - scattered among various websites, brochures and other documents.

“Eventually,” says Ray, “they’ll sell this concept to other manufacturers and I’m sure everyone will jump on the opportunity.”

Currently, however, Rosenfeld Kidson is alone in their access to this impressive tool, which is available for all rusticated and vertical weatherboard systems, as well as their INTERSET recessed window flashing system (now available for rusticated as well).

“We’ve been responsible for several key systems over the last 20 years. Innovation is great,” says Ray, "but often innovation creates challenges around buildability. This development, on the other hand, removes them. Working Spec creates a synergy between the creative mind and technical aspects of the build.”

Want to learn more about the New Zealand specialist timber company that’s always on the cutting edge? Check out Rosenfeld Kidson on ArchiPro today.

Nordic style: a monumental leap for cedar cladding

Detailing recessed aluminium windows within a cedar facade has been a challenge for New Zealand architects for over a decade, but it has been a particularly prominent one of late as we look towards a distinctly Nordic influence in our residential architecture.

Words by ArchiPro Editorial Team - 24 July 2017 - 2 min read

Launched earlier this month, a new system has the industry buzzing. That’s because it’s allowing architects to easily achieve recessed windows with traditional aluminium joinery and vertical or horizontal cedar or larch cladding to create a contemporary, minimalist aesthetic.

The need for this sort of solution was initially born out of the visual requirements of a developing vernacular that draws inspiration from the clean, cool lines of minimalist Nordic architecture. “Until now, it was a challenge for architects to detail recessed aluminium windows for cedar or larch cladding. Now there is an easy and compliant solution that ensures weathertightness and thermal efficiency,” Rosenfeld Kidson’s Mark Liggins says.

The need for this sort of solution was initially born out of the visual requirements of a developing vernacular that draws inspiration from the clean, cool lines of minimalist Nordic architecture. “Until now, it was a challenge for architects to detail recessed aluminium windows for cedar or larch cladding. Now there is an easy and compliant solution that ensures weathertightness and thermal efficiency,” Rosenfeld Kidson’s Mark Liggins says.

“The INTERSET recessed window flashing system for cedar cladding represents a true technological advance. It’s a natural progression on our 45mm batten system, which provides the depth to pull the flashings back to the frameline creating a natural 65mm deep recess.”

Because the windows are recessed to the warmer framing line as opposed to the outer cladding layer as was traditionally the case, the system has a unique thermal benefit.

“The INTERSET system has no outer fixings penetrating the underlay or going through to the frame so it’s a huge leap for weathertightness too, which will improve the productivity of cedar and larch facades long term.”

In Europe, recessed windows in timber facades are commonplace. There, the building methodologies are very different to ours, with thicker walls and double battens that have the natural recess our buildings don’t. “This is where the problem has been for our architects, who are trying to achieve the Northern European aesthetic with a very different system of building,” Mark says.

Briar Bank House project by Rafe Maclean Architects uses the INTERSET® Recessed Window Flashing System with vertical cedar cladding

“Aesthetically, this tested system allows architects to easily create a clean, contemporary look by concealing the aluminium joinery and creating an uninterrupted flow from the timber plane to the glass plane.”

Architects, especially in situations where there are covenants over the design, have not had an easy solution to create recessed aluminium windows in timber cladding when they are required. “This is a simple solution to detail and install,” Mark says.

The system is comprised of a set of aluminium flashings and thermoplastic stop-ends that interlink to form a picture-framed window recess. The arrangement enables aluminium windows to be recessed 65mm to the framing line from the outer facade.

INTERSET flashings are used in conjunction with the Rosenfeld Kidson CodeMark certified 45mm structural cavity system for vertical or rusticated Western Red Cedar and European Larch weatherboards.

Get in touch with Rosenfeld Kidson on ArchiPro here to discuss the possibilities of this new technology.

This Dalman Architecture project uses the INTERSET® Recessed Window Flashing System with random width cedar cladding

NZ Architects leading the way for responsible specification

Check out our Joint Presentation with Rosenfeld Kidson & FSC New Zealand at Jasmax here

FSC® 100% certified hardwoods TONKA and GARAPA finding favour with specifiers and the construction industry alike.

Rosenfeld Kidson has recently supplied timber to a number of high profile projects further enhancing Auckland’s spectacular waterfront.

TONKA has become the hardwood timber of choice for public space developments in applications such as boardwalks, wharfs, bridges and other structural end uses; as well as heavy exterior furniture, shelters and residentially for pergolas and posts etc.

In addition to its environmental credentials, it is favoured for its superior characteristics of strength and durability, its attractive colour and great weathering properties.

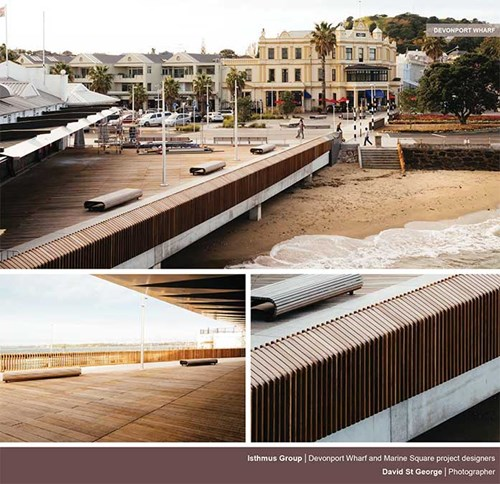

Below images show the newly completed Devonport Wharf and Marine Square project. A legacy North Shore project, this major infrastructural upgrade was delivered jointly by Auckland Council and Auckland Transport. Taken together with the new library, also clad in Western Red Cedar supplied by Rosenfeld Kidson, this represents the most significant Council investment in Devonport for a very long time.

FSC 100% certified timbers supplied to the project include Tonka for the boardwalk material, Iroko used as the handrail and Massa seating.

GARAPA is becoming the preferred hardwood timber choice for smaller dimension applications such as exterior furniture and joinery, public boardwalks and domestic decking. It has all the benefits of a stable and durable hardwood, with the added features of being from an environmentally responsible source and having negligible tannin release.

GARAPA is an attractive honey-brown colour and has a fine texture that weathers very well and is not prone to checking/splitting.

PEFC certified AUSTRALIAN hardwoods have also made a resurgence, being specified for a number of large local body projects in Auckland. These include SPOTTED GUM supplied by Rosenfeld Kidson to the Westhaven Promenade project and JARRAH for another large downtown project being completed towards the end of the year.

Rosenfeld Kidson & Co. Ltd is a specialist timber merchant and importer, incorporated in 1930. We stock New Zealand’s largest range of over fifty species, both imported and locally grown and are the only importer to offer a full and comprehensive range of FSC 100% certified hardwoods.

We distribute to the construction industry, joiners, furniture manufacturers, cabinetmakers, boatbuilders and flooring contractors throughout New Zealand, primarily via selected reseller merchants from our sales and warehousing facilities based in Auckland and Christchurch.

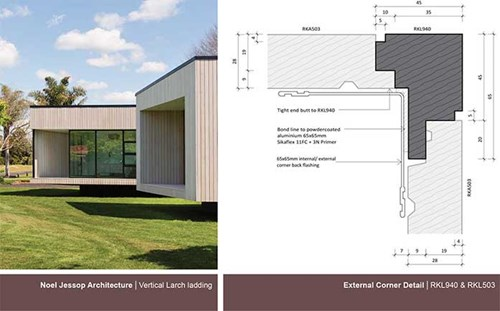

Larch Cladding Making a Statement

Larch cladding is now available in our Vertical, Rusticated, Bevel Back and Board and Batten cladding systems. Customised corner and jamb detailing have been developed to effortlessly blend with our range of 28mm thickness Vertical and new Rusticated weatherboards.

Larch has a very pale appearance with a strong grain pattern and tight knots. The extreme climate from which Larch originates produces slow growing conditions, resulting in close growth rings and a fine grain. Larch also possesses a high resin content and coupled with its naturally high density has great durability properties. These characteristics produce a timber of great depth and texture that is a unique alternative to other timber claddings in the market. Factory oiling in a our ‘Larch-specific’ range of Dryden Woodmaster blondes and silver greys further compliment this distinctive material.

FSC® 100% certified hardwoods supplied to Devonport Wharf upgrade

Rosenfeld Kidson recently supplied 200x75mm Tonka structural wharf decking for the Devonport Wharf upgrade. In addition to its environmental credentials, Tonka is favoured for its superior characteristics of strength and durability and also its attractive colour and weathering properties.

In addition, FSC 100% certified Iroko was used for the feature handrail and Massa for the street furniture. Follow this link to read an article on this project from the landscape architect involved Isthmus Group.

Rosenfeld Kidson provide solid timber flooring for Welcome Shelter at Longbush Ecosanctuary

The Longbush Ecosanctuary Welcome Shelter is an innovative environmental education space designed as a gateway for visitors to a very special environment, which includes several critically endangered native species. The ecosanctuary is approximately 120 hectares and over the past 15 years has been the rapidly restored through the efforts of Jeremy and Dame Anne Salmond.

The Longbush Ecosanctuary Welcome Shelter is an innovative environmental education space designed as a gateway for visitors to a very special environment, which includes several critically endangered native species. The ecosanctuary is approximately 120 hectares and over the past 15 years has been the rapidly restored through the efforts of Jeremy and Dame Anne Salmond.

Constructed by a team of passionate volunteers from donated materials, including timber flooring from Rosenfeld Kidson, the Welcome Shelter utilises very simple construction techniques. The aim of the shelter is to use minimal architectural resources while promoting active stewardship of our natural environment. The Welcome Shelter facilities are free of charge for all visitors, including school groups, ecologists and tourists.

Rosenfeld Kidson were proud to have the opportunity to provide Australian solid hardwood flooring for the Welcome Shelter, as we found the project intent was in line with our business values.

The project was generated and designed by the award winning designer Sarosh Mulla. Mr Mulla’s current doctoral research focuses on creating innovative forms of architecture for the New Zealand tourism industry, while continuing to promote the role of the architect as a leader within communities.

The design of the structure draws on the framing techniques of the picturesque, but applies these through contemporary forms, which promote active engagement with the environment. Rather than simply viewing the landscape, visitors are encouraged to take part in the environmental restoration occurring at the ecosanctuary, through the programs offered at the Welcome Shelter.

A large steel and fabric canopy provides shelter from the sun and rain for an outdoor classroom created on the hillside. Below the roof the form of this classroom is defined by the position of three timber enclosures and small retained gardens.

The design plays with the connotations of natural and synthetic materials in the setting of the recovering environment. Each timber enclosure provides a different service, including the storage of teaching material, ablution facilities and an office for the site ecologist. This office opens up to the exterior with a large drawbridge to create a level platform on teaching and demonstration days.

Another enclosure includes a roof deck from which a stunning view of the valley can be appreciated. This deck is accessed via a traditionally made greenwood ladder, made from a Manuka tree harvested from the building site.

With the removal of invasive pests and weeds, alongside the planting of hundreds of thousands of native trees, the diverse ecology at Longbush is beginning to thrive again. Never before in New Zealand history has such a large and diverse group of volunteers and sponsors created a piece of public architecture.

The Welcome Shelter creates a new benchmark for high quality, community generated, architecture that responds to the needs of the local environment.

All photos courtesy of Sarosh Mulla.

As featured in Trends

This contemporary suburban home designed and built by multi-award winning Cameron Ireland Builders, with architect Jack McKinney, is one of several modern homes built on the site by Ireland.

This contemporary suburban home designed and built by multi-award winning Cameron Ireland Builders, with architect Jack McKinney, is one of several modern homes built on the site by Ireland.

The garage and floating box are clad in black-stained vertical cedar weatherboards supplied by Rosenfeld Kidson together with Garapa hardwood decking and cedar fence palings.

Stunning Koia House Showcases Wanaka Style

Koia Architects select innovative 45mm structural cavity system & Rosenfeld Kidson timbers

- Western red cedar cladding blends Southland exterior aesthetics of high country resilience, and provides interior glow.

- Innovative new 45mm structural cavity system enables improved weather protection and ventilation while allowing more depth around windows for a clean exterior profile.

- FSC 100% certified Garapa hardwood decking timber marries perfectly with the chosen materials and surrounds.

Koia Architects designs Law House in the Wanaka hills

The Law house is a superb example of New Zealand architecture with cool clean lines and a breath-taking outlook over Lake Wanaka.

Designed to complement and enhance the spectacular natural landscape, the Law House utilises its great location and aspect to maximise views and energy efficiency. Wide windows and decks on two sides provide a nearly continuous outlook and a feeling of being connected to the dramatic and spacious surroundings.

"We have worked hard to ensure the building blends with the environment. The timber cladding is a very important component of this. The Rosenfeld Kidson corner and jamb profile is a beautiful way to detail these junctions. The window flashing system we developed has been refined to work with this and ensure the water protection, drainage, air seal and insulation all align as they should."

Tony Koia, Principal Architect, Koia Architects

For the house’s distinctive exterior cladding Koia Architects chose Western Red Cedar. Cedar has a very low shrinkage factor and therefore is very stable.

"Many builders in Wanaka will only use cedar as their timber cladding. The climate has a very low humidity which causes significant shrinkage. It can cause damage to any antique furniture on the inside of a house and the exterior of a house is a much harsher environment." - Tony Koia.

Western Red Cedar varies from dark brown to pink and readily accepts stains and oils to provide a wide choice of palette. Available in an endless variety of profiles, finishes and coating products, cedar provides designers and architects with great design flexibility.

Western Red Cedar was also employed for internal panelling throughout the Law House.

"We wanted to create a 'warm glow', reminiscent of a ski lodge, to the living room. In a bright large glazed area, cedar panelling absorbs the light and minimises glare.

Using cedar for the interior has worked really well to link the exterior to the interior, and combine with the local schist and break up other flat painted surfaces. - Tony Koia.

The 45mm structural cavity system utilises a structural 45mm Radiata cavity batten with vertical shiplap Cedar weatherboards. The ventilated cavity batten is fixed to the wall framing without requiring additional supporting dwangs or nogs meaning it is much easier to install.

The primary benefit of a 45mm structural cavity system is that the cladding only needs to be fixed to the batten itself and not through the building envelope, helping to maintain the integrity of the air seal. The 45mm structural cavity also allows for improved drainage and ventilation.

"With the 45mm structural cavity system, the exterior nails do not penetrate the RAB board lining, which means there is significantly reduced risk of water penetration and better pressure equalisation.

There is less risk of water or air leakage, and the better ventilation provided by the system means better drying. Windows and doors can be recessed to the insulation and RAB board line to ensure these are a continuous line around the perimeter." - Tony Koia.

The greater cavity space provided by the 45mm structural cavity system allowed the recessed windows in the Law House design to be brought forward to the outer line of the framing, rather than recessed behind it.

Attractive, hard wearing timbers that suit Wanaka’s stunning landscape

Koia Architects specified Garapa for the striking deck of Law House. Garapa has a history of success in New Zealand, tried and tested in our country’s varied climatic conditions for almost a decade.

Garapa is a honey brown colour with a very fine finish which appealed to Koia Architect’s Tony Koia on an aesthetic level.

"I think the colour and grain of Garapa wood is better suited to Wanaka than most timbers, as it blends beautifully with the natural surroundings." - Tony Koia.

Because Rosenfeld Kidson’s Garapa is a kiln-dried timber, it delivers great properties of stability in addition to its great durability. Garapa also does not suffer end-checking or leach staining tannins in the way some other hardwoods can.

As well as having many superior properties compared to other hardwoods available on the market, Garapa is environmentally certified as FSC 100%, which is the most stringent third-party environmental standard available.

"We had designed an outdoor bath which is hidden under a removable deck cover. This meant we needed a timber that wouldn’t leach into the bath, so we wanted an alternative to Kwila. We also wanted a more sustainable hardwood, and the colour of Garapa made it an attractive alternative." - Tony Koia.

A great builder ensured the vision was faultlessly realised

"It is essential to have a quality builder at any time and Tony Quirk Builders have been great. Their attention to detail has been particularly impressive in aligning the cedar sacking to the interior to the doorway openings; and it is this quality that is needed to create architecture." - Tony Koia.

About Koia Architects

Koia Architects was established in Auckland, New Zealand in 1995 by architect, Tony Koia. The practice has expanded over the years and a second office was established in Queenstown in 2004. Each commission is special and unique. Every client brings a different hierarchy of requirements and Koia Architects identify these at the outset - whether they are aesthetic, quality, time or budget constraints - so a successful outcome is achieved. For more see www.koia.co.nz.

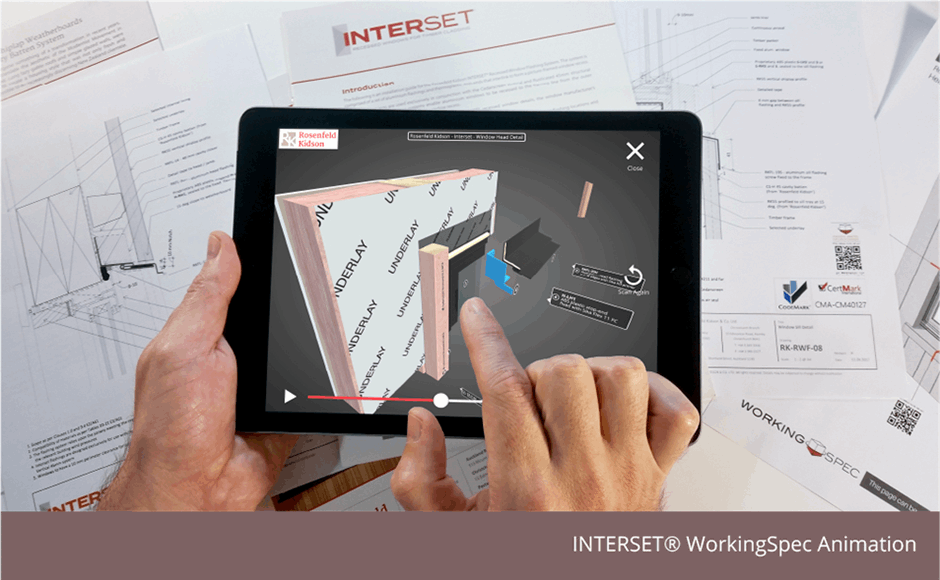

WorkingSpec Launches with INTERSET®

Rosenfeld Kidson’s INTERSET® Recessed Window Flashing System can now be viewed as an interactive 3D animation to assist interpretation and installation of this clever solution.

Rosenfeld Kidson has the fortunate opportunity to be the first to embrace this revolutionary platform.

WorkingSpec allows Manufacturers, Architects and Engineers to communicate their design details to the trades in a more accessible way. Often the existing information is platform and software specific and limits a user's ability to access the information easily.

Many times, information contained in a detail is missed or not interpreted correctly when viewed on the 2D platform of paper and digital documents. WorkingSpec works to compliment the 2D platform and enhance it through specific QR codes, placed on the detail drawing, product material or packaging.

The app is used to scan the code and view the 3D-animated, interactive model on a Tablet or Smartphone.

Where can the app be used?

• Bespoke Architectural details

• A better understanding of existing systems

• Training staff, Builders or Specifiers in using or assembling your product

• Selling your product

It's easy!

1 – Download the WorkingSpec app from the Apple app store or Google Play.

2 – Find and scan the WorkingSpec QR code on the participating Manufacturer’s brochure, drawing or packaging.

(to make it even easier here is one below on the screen)

3 – View the interactive model.

For more information send a mail to info@workingspec.com